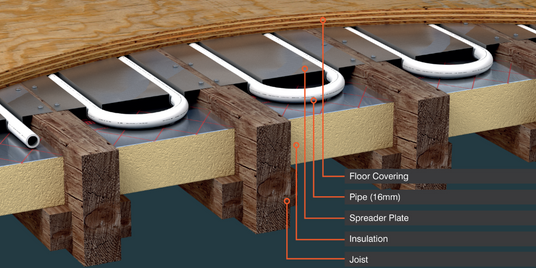

Spreader Plates

- Aluminium spreader plates are fixed to joists with screws or nails.

- Plates have 16mm pre-formed grooves set at 200mm centres for ProWarm™ European Standard Pex-Al-HDPE pipes.

- Batons are installed on the sides of the joists, about 70mm from the top, if joists are deep enough.

- 50mm foil-faced insulation (e.g., Celotex or Kingspan) is cut and placed onto the batons.

- Pipework is clipped directly into the grooves of the spreader plates for optimal heat distribution.

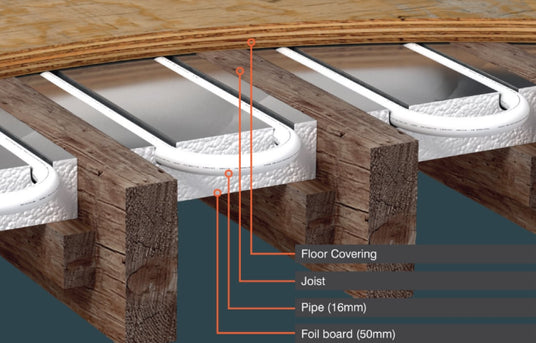

In-Joist Batten

- These innovative boards combine the functionality of both spreader plates and insulation in one system.

- The 50mm thick XPS insulation panels feature pre-formed grooves at 200mm centres to hold the pipes.

- The entire board is coated with aluminium foil to ensure even heat distribution across the floor above.

- In a standard installation, batons are fixed to the sides of the joists about 70mm from the top.

- The boards are then placed on top of the batons, and the pipes are clipped directly into the pre-formed grooves for easy installation.

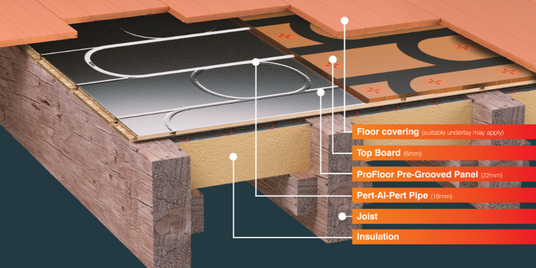

ProFloor

- ProFloor pre-grooved panels allow underfloor heating pipes to heat the room efficiently.

- Ideal for timber suspended floor structures with joist spacings of up to 400mm centres.

- The system uses pre-grooved flooring panels specifically designed for 16mm pipes.

- ProFloor Panels help reduce both material costs and installation time.

- Installation is quick and straightforward, requiring no additional adhesive and eliminating the need for extra drying time.

Not sure where to start? Let us help!

Answer a few questions and we’ll get you on your way