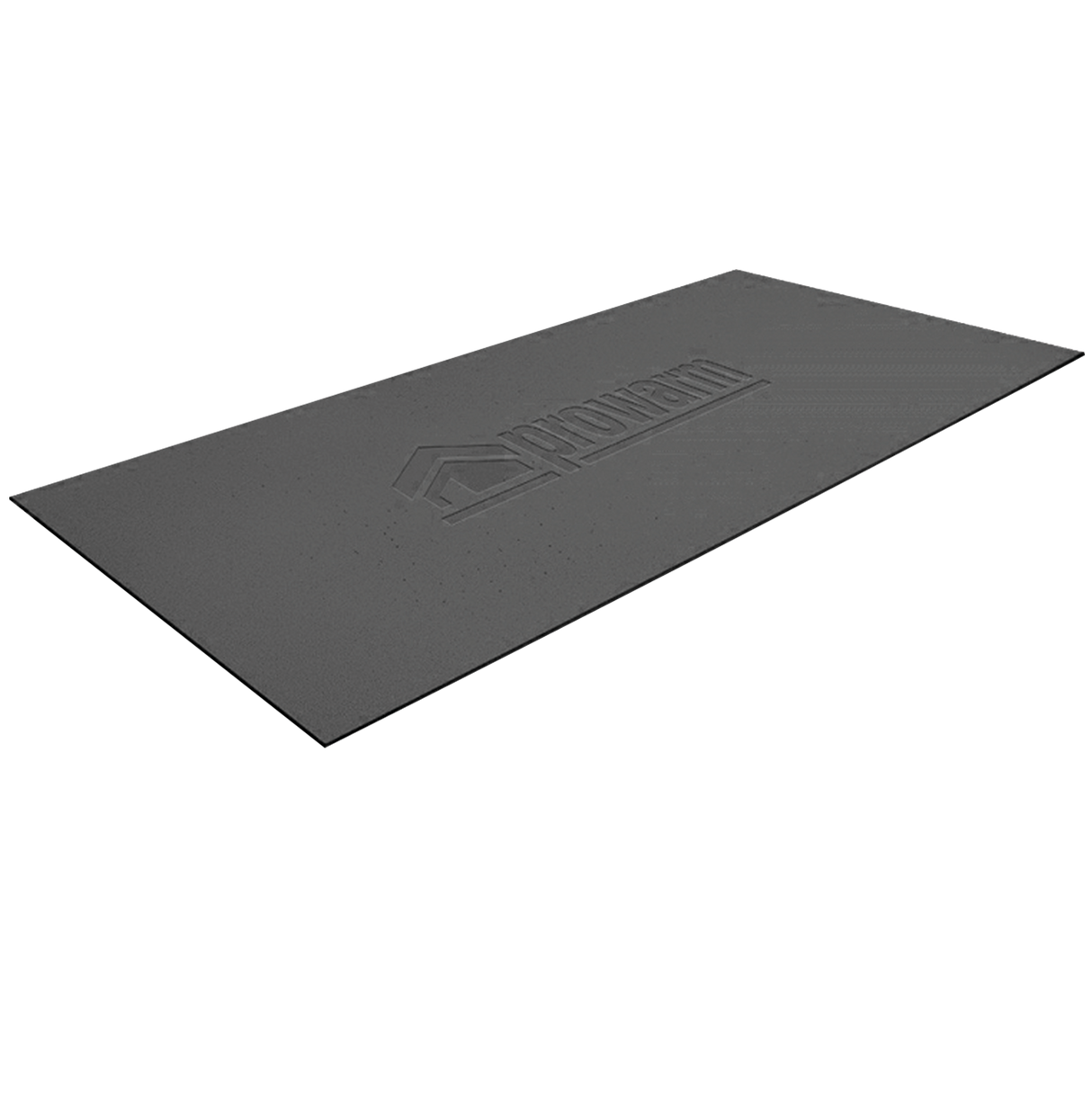

ProWarm Insulation Board - XP-Pro

Add your area dimensions and we'll calculate how many boards you need

Add your area dimensions and we'll calculate how many boards you need

Add your area dimensions and we'll calculate how many boards you need

Buy now, Pay with Klarna

Buy now, Pay with PayPal

Description

Description

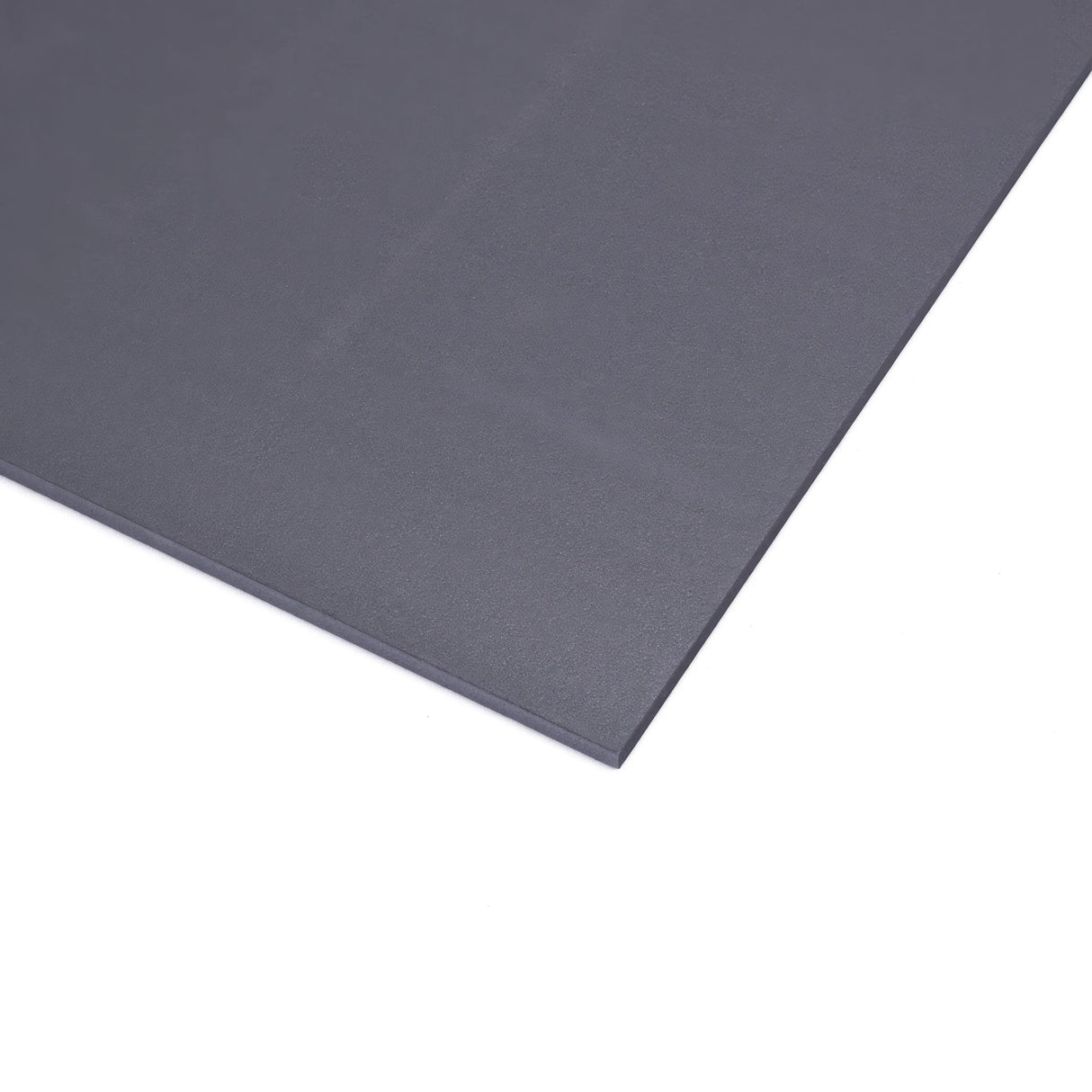

ProWarm Insulation Board - XP-Pro are specially designed to provide excellent insulation and support for our electric underfloor heating systems on concrete or screeded floors. With dimensions of 1200mm x 600mm per board, each board covers an area of 0.72m², ensuring efficient coverage for your installation.

Key Features:

- High-Quality Insulation: XP-PRO Insulation Boards offer superior thermal insulation properties, making them an ideal choice for improving the energy efficiency of your underfloor heating system.

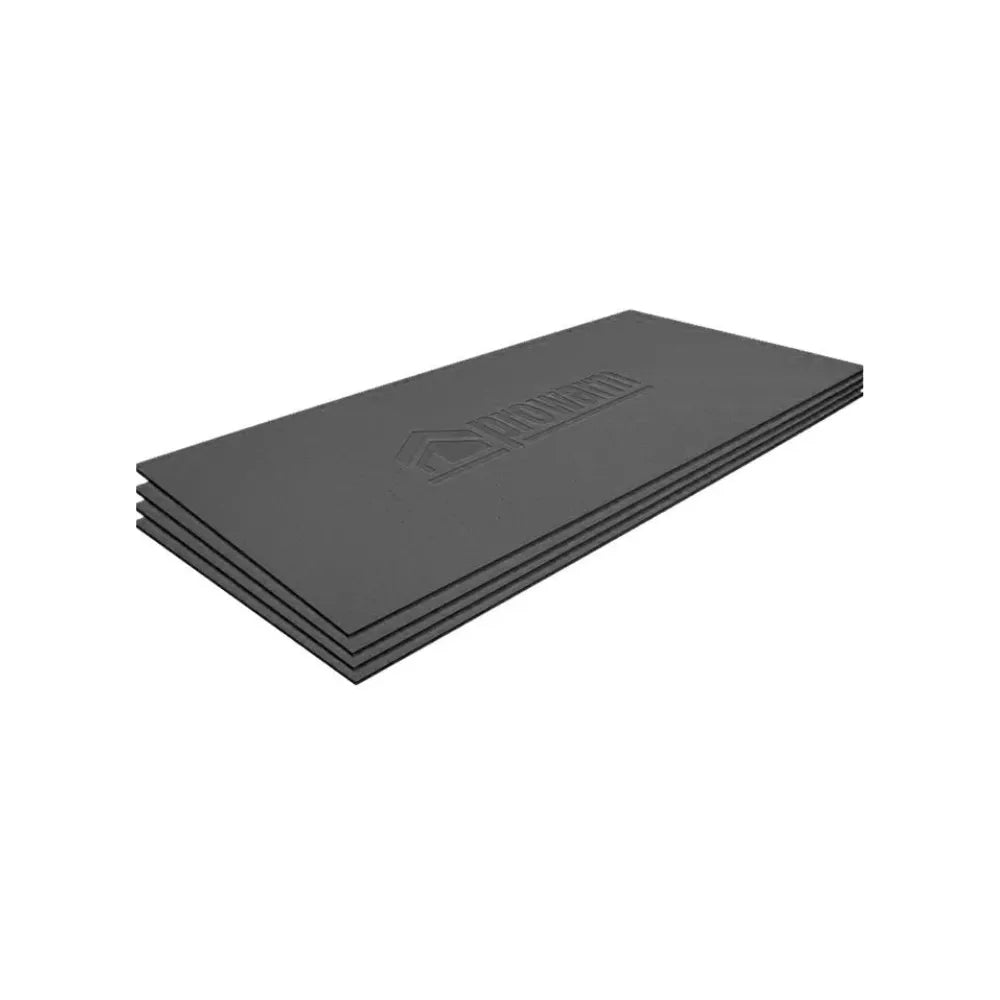

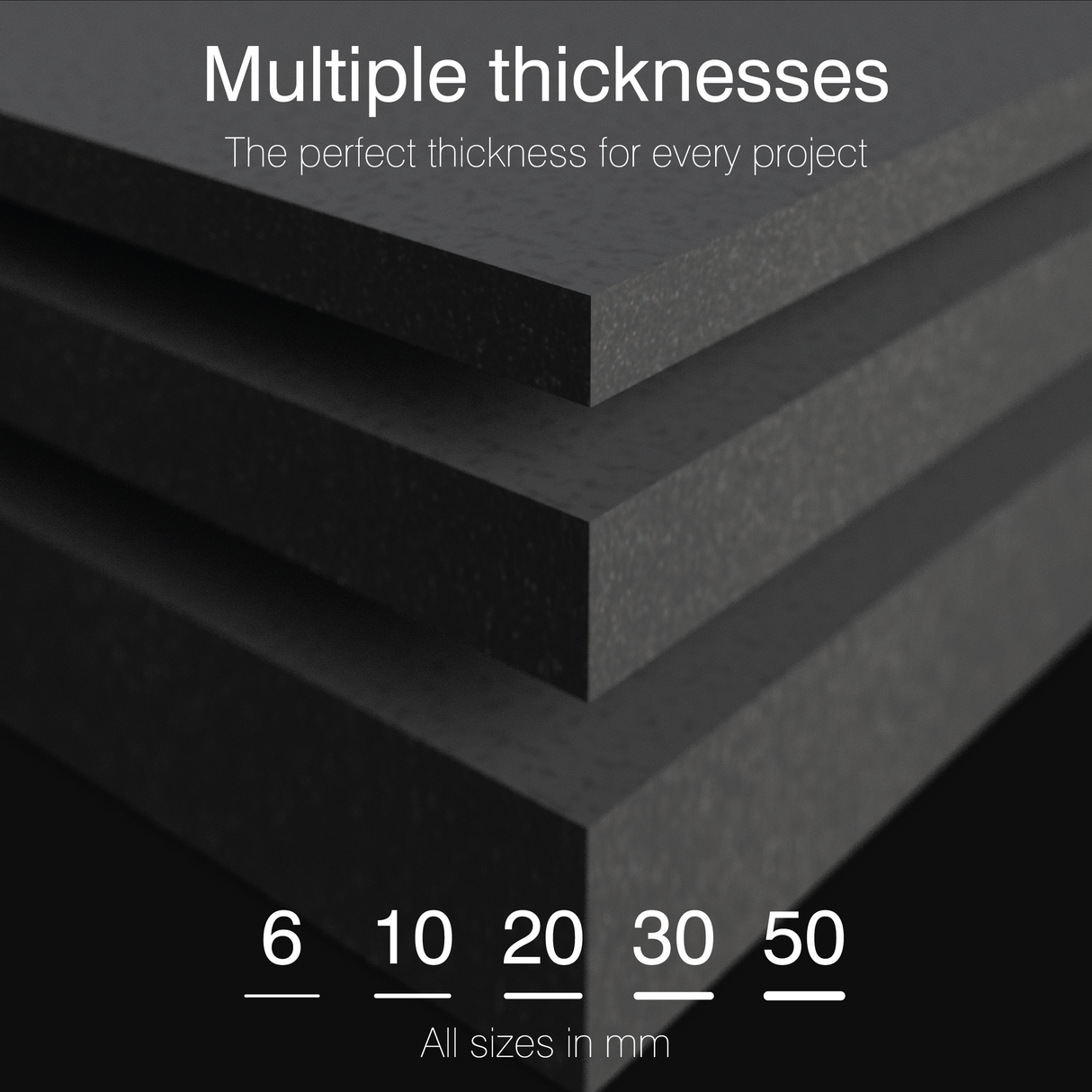

- Multiple Thickness Options: Available in 6mm, 10mm, 20mm, 30mm, and 50mm thicknesses, these boards provide flexibility to meet various installation requirements and insulation needs.

- Compatibility with Underwood Heating Systems: XP-Pro boards can be used as top-quality insulation for underwood heating systems. Simply lay the boards in a staggered brick bond pattern and place the heating mat over the top for a seamless installation.

- High Compressive Strength: With a compressive strength of 30 tonnes/m², these boards offer excellent stability and durability, ensuring long-lasting performance.

- Lightweight and Cost-Effective: The lightweight nature of XP-PRO boards simplifies handling and installation while keeping the overall project cost low.

- Approved by UltraTile: These insulation boards are fully approved by UltraTile, a trusted name in the industry, guaranteeing their reliability and quality.

Installation

The installation method for ProWarm XP-PRO boards depends on the type of heating system being installed:

- Foil Underfloor Heating: Lay the boards in a staggered brick bond pattern, and then place the foil heating mat directly over the boards for optimal performance.

- Underfloor Heating Mats: When using XP-PRO boards with underfloor heating mat systems, the boards must be securely fixed to the subfloor using a suitable flexible tile adhesive. This ensures stability and proper heat distribution for your underfloor heating system.

Experience the benefits of superior insulation and efficient underfloor heating with ProWarm XP-Pro Insulation Boards. With their high-performance features and easy installation process, these boards are the perfect choice for achieving a comfortable and energy-efficient living space.

Specifications

- Coverage per board: 0.72m²

- Dimensions: 1200mm x 600mm

- Available thicknesses: 6mm, 10mm, 20mm, 30mm, 50mm

- Compressive strength: 30 tonnes/m²

- Installation method: Lay in staggered brick bond pattern (foil underfloor heating heating system), Fix to subfloor with flexible tile adhesive (underfloor heating mat system)

Reviews

Reviews

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Not sure where to start? Let us help!

Answer a few questions and we’ll get you on your way