Description

Description

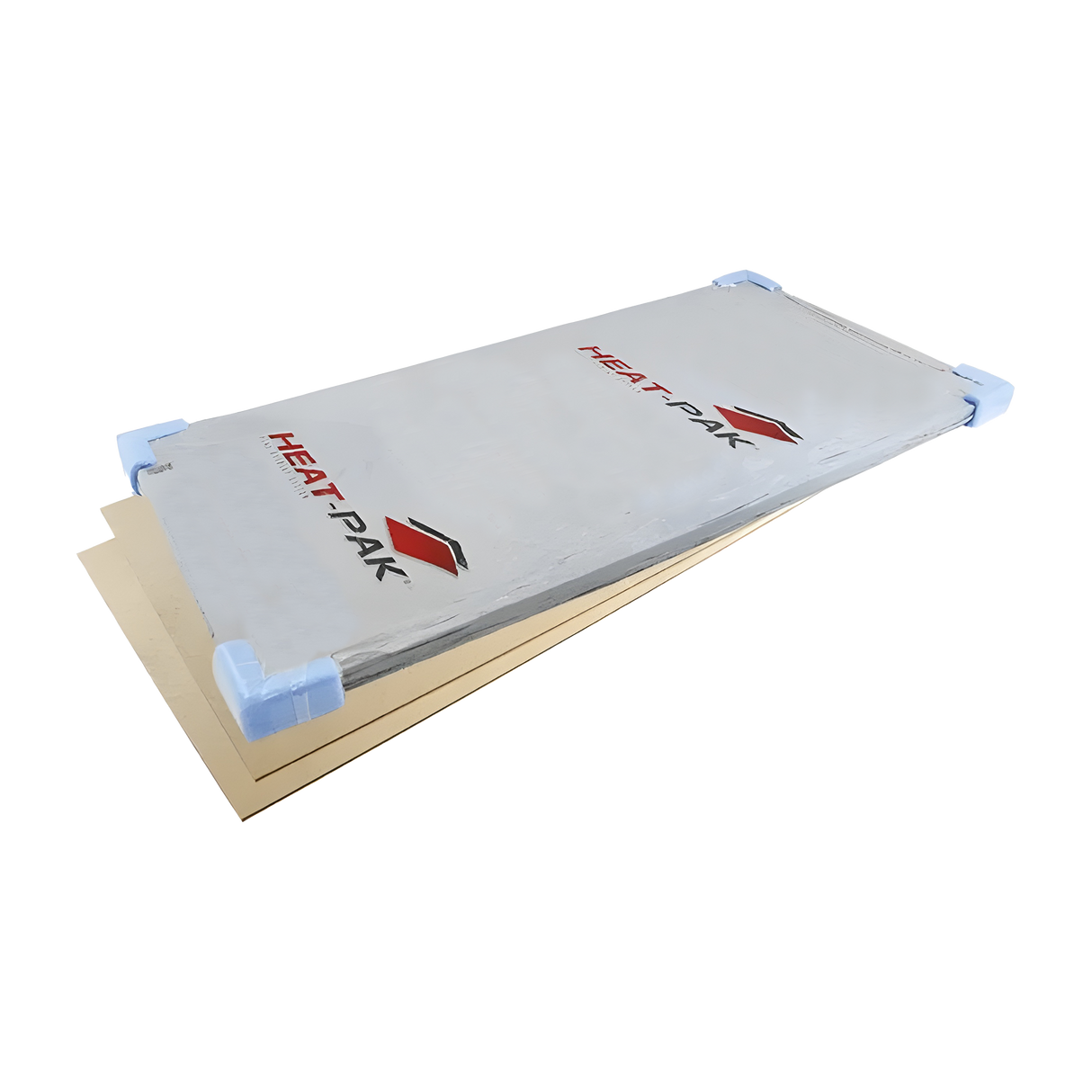

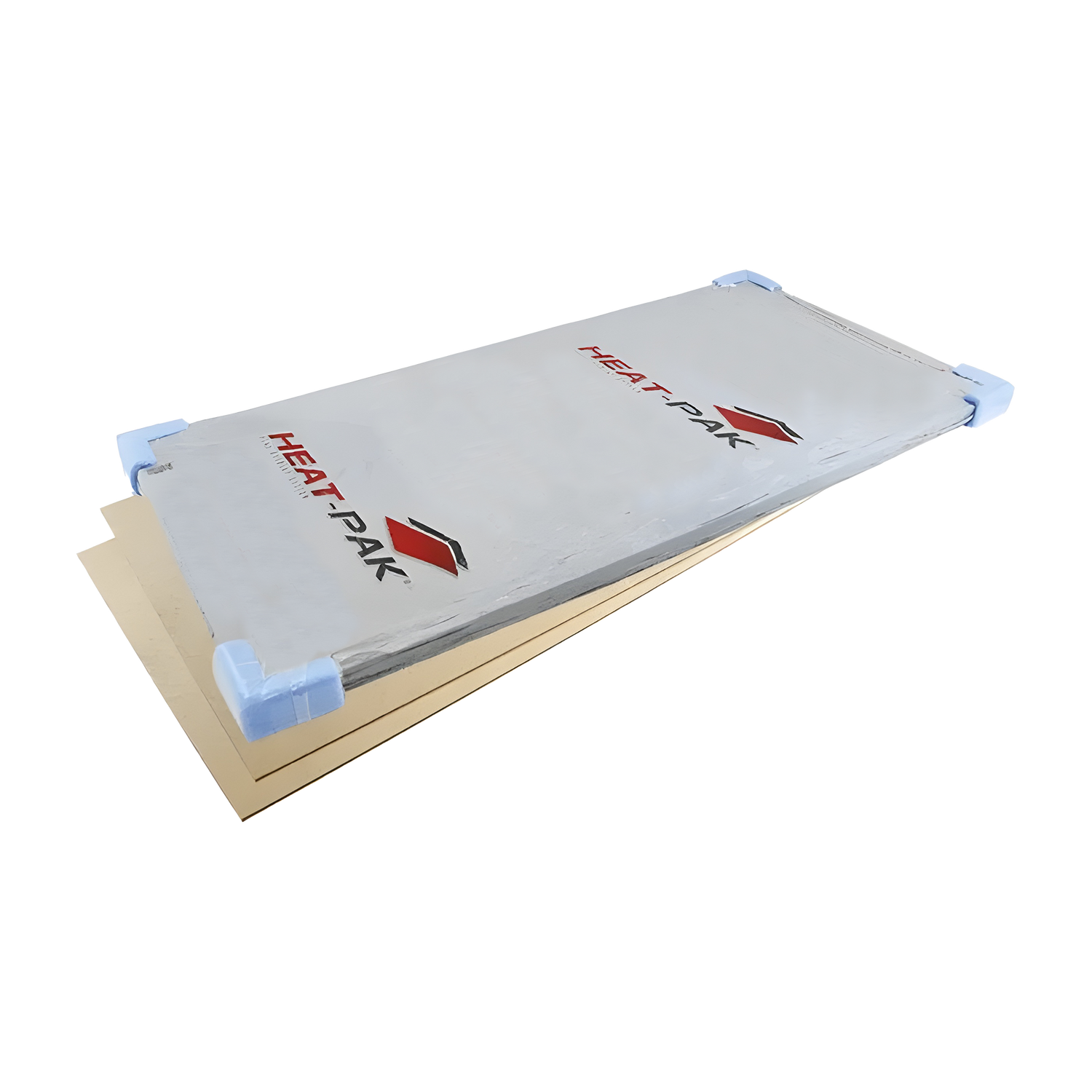

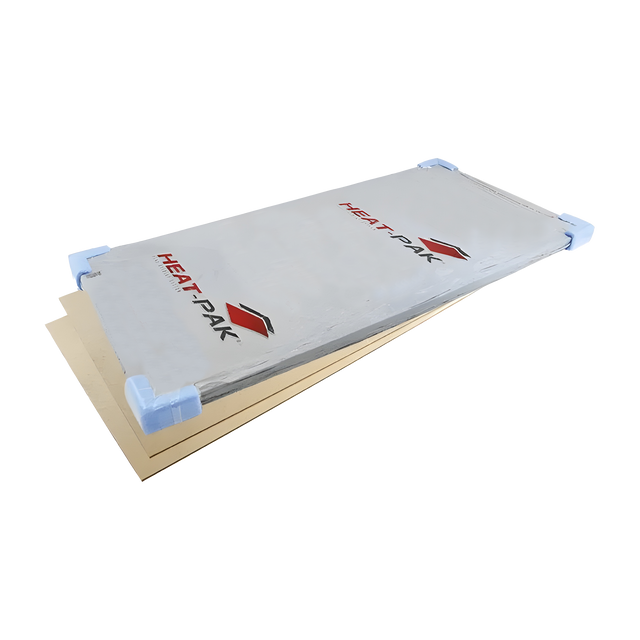

The Heat-Pak Dual Overlay System is the most stable overlay system designed for electric foil underfloor heating mats and water underfloor heating LoFlo Lite panels.

Key Features:

- Optimal Subfloor Solution: Heat-Pak is a free-floating subfloor system specifically designed for installation over electric underwood foil underfloor heating and water underfloor heating LoFlo Lite panels. It provides a smooth and stable base, ensuring the durability and longevity of the floor-coverings.

- Seamless Surface: The twin layers of Heat-Pak panels feature an overlap joint configuration, resulting in a seamless surface. This eliminates the visibility of lines or patterns that may show through shiny floor finishes.

- Wide Range of Floor Coverings: Heat-Pak is compatible with various floor coverings such as carpet, linoleum, vinyl, and cork, offering versatility in design choices.

- Easy and Quick Installation: Heat-Pak is simple to install and much faster and easier to use compared to traditional smoothing compounds. It is a dry process that minimizes mess and requires no setting time, allowing for immediate flooring installation.

- Enhanced Heating System Installation: Heat-Pak simplifies the installation of electric cable, mat, foil, or film heating systems, offering a more convenient alternative to the wet screed method. It ensures the heating elements remain securely in place, keeping the entire system flat and protected.

- Efficient Heat Transfer: The Heat-Pak system has a very low thermal resistance (Rm value of only 0.047), allowing heat energy to pass quickly and efficiently to the surface. This results in a fast warm-up time and maximum comfort.

- Incorporation of Insulation: Heat-Pak enables the inclusion of a suitable insulation layer below electric systems, maximizing energy efficiency and performance.

- Premium Quality: Heat-Pak is composed of high-quality MDF with 3mm baseboards and 4mm topboards. Each board is coated with a special interactive contact adhesive, ensuring a strong and permanent full-surface bond. Strict quality controls during production guarantee excellent results and a trouble-free installation every time.

Elevate your floor heating system with the Heat-Pak® Dual Overlay System. Its stability, ease of installation, and compatibility with various floor coverings make it the ideal choice for creating a comfortable and visually appealing space.

Specifications

| Size | 1200mm x 600mm |

|---|---|

| Top Board Thickness | 4mm |

| Base Board Thickness | 3mm |

| Composition | MDF, fitted with an interactive adhesive |

| Density (kg/m3) | 770 |

| Bending Strength kg/cm2 | >40 |

| Humidity (%) | 4-10 |

| Thermal Rm value [m2.K.W.-1] | 0.047 |

| Fire Class, DIN4102 | B2 |

Installation

- The first row of baseboards is created by splitting boards in half lengthways and turning the cut edges towards the wall.

- The first piece is shortened to 3/4 of its length with both cut edges against the walls in the corner. Lay out the other pieces end to end in a line along the wall, adhesive side up, leaving the protective film in place

- Leave an expansion gap of 8-10 mm all around the perimeter and around pipes and other fixed objects, this also applies to the final floor finish.

- Boards in the second row are laid out in the same direction as the first row.

- Start by cutting a board to 1/4 of its length and place this piece, with the cut end to the wall, next to the first row.

- Now place a full sized baseboard end to end with it and alongside the first row. The large off-cut will be used to start the third row of baseboards.

- Do not remove the protective film at this stage and keep the job clean and free from dust.

Top Boards

- The top boards are laid in the same direction as the baseboards, but with the adhesive side down. The first board of this row is full size and positioned into the corner overlapping both the first and second rows of baseboards.

- If the board fits neatly into the corner no trimming is required, in which case it can be lifted out and the plastic film can be peeled back from the baseboards that it will cover.

- Avoid removing more film than is necessary to accommodate the top board on the adhesive. The top board is carefully repositioned and adjusted for alignment, at the same time the baseboards should be checked for any gaps and adjusted if required; finally the top board is fixed in place by tapping down with the rubber mallet.

- For the best result it is important to keep the joints between the top boards as tight as possible. The easiest way to achieve this is by starting the second row of top boards with a half-length piece, followed by a full board and pushing all the edges tightly together before tapping down.

- Adding further boards, alternately, to the first two rows keeps the lines straight and so prevents gaps from developing.

- Due to possible influences of air humidity, glue the floor covering on the Dual Overlay no later than 48 hours.

- Every room should be fitted separately, leaving an expansion gap of at least 8 -10 mm and 16mm in door openings when Dual Overlay is continued in the adjoining area.

- If the floor covering is to be glued onto the total surface and should not to exceed the edges of the Dual Overlay Boards.

- This method of installation will provide a stable surface for the floor finish to rest on and avoid any joints showing through the final floor finish.

Finish

Now you have installed the Dual Overlay boards you can either glue your final floor finish to the boards as a final layer or simply lay it freely upon them. Before installing the final floor finish test the foil heater(s) and floor sensor to ensure that no damage has occurred during the installation.

This method of installation will provide a stable surface for the floor finish to rest on and avoid any joints showing through the final floor finish. Now you have installed the Dual Overlay boards you can either glue your final floor finish to the boards as a final layer or simply lay it freely upon them. Before installing the final floor finish test the foil heater(s) and floor sensor to ensure that no damage has occurred during the installation.

Please note: Heat-Pak Dual Overlay must NOT be used in bathrooms, wet rooms, en-suites, or any other wet areas as they will expand upon contact with moisture. For carpet or vinyl installations in these areas, it is necessary to use an underfloor heating mat with self-levelling compound.

Reviews

Reviews

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Not sure where to start? Let us help!

Answer a few questions and we’ll get you on your way