What is an Underfloor Heating Manifold?

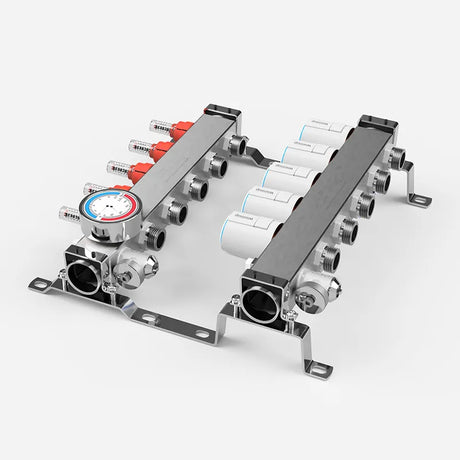

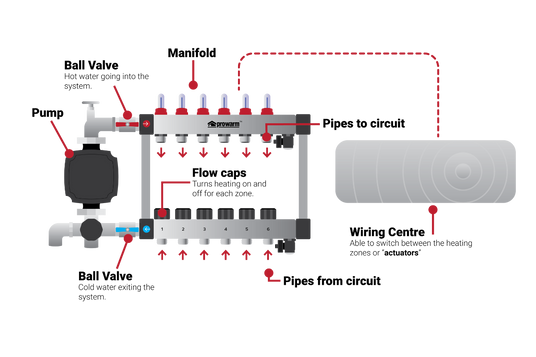

An underfloor heating manifold is the control centre of the water underfloor heating system. It is engineered to deliver heat from the source to all areas throughout the underfloor heating pipework. An underfloor heating manifold is quite a complex piece of equipment with a wide range of functions, controlled by various valves and gauges. Its main purpose, however, is to regulate temperature, pressure and flow levels around the complete system, including individual zones.

Wiring Centre

A wiring centre is installed at the manifold and allows you to control individual zones. This simplifies the connections between the actuator, pump, valve and boiler and helps to improve efficiency.

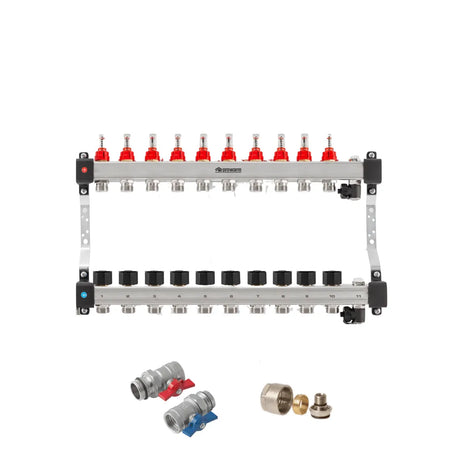

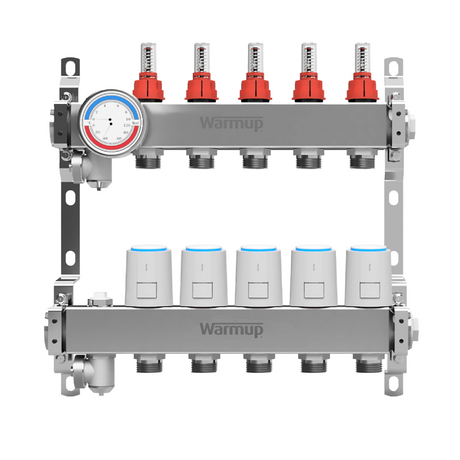

Manifold Mixing Unit

This component mixes heated water from the main heat source with cooler water from the floor loops, helping to regulate pressure, flow rate and temperature.

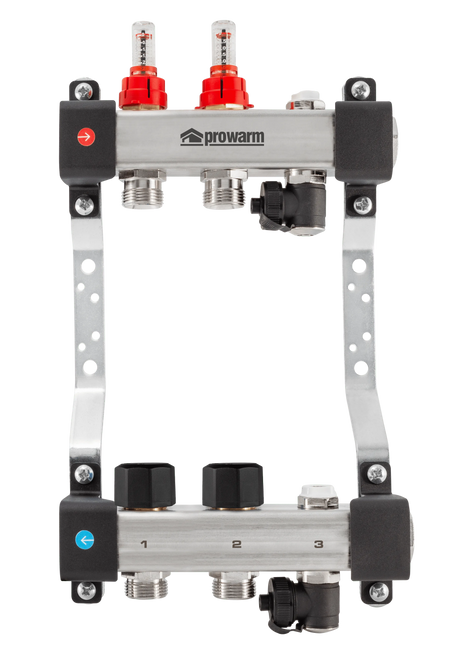

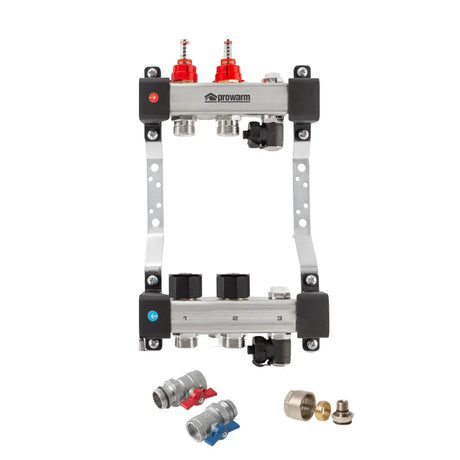

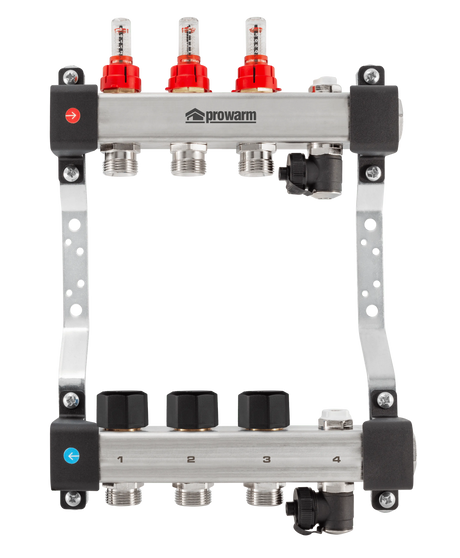

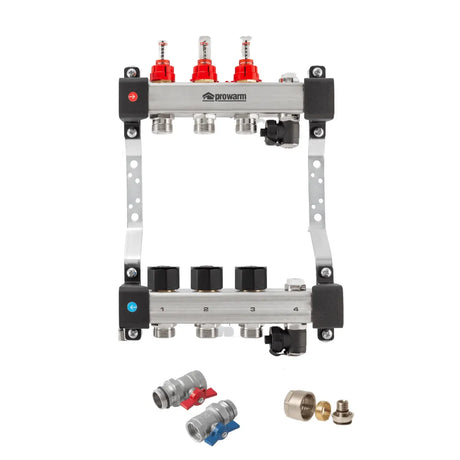

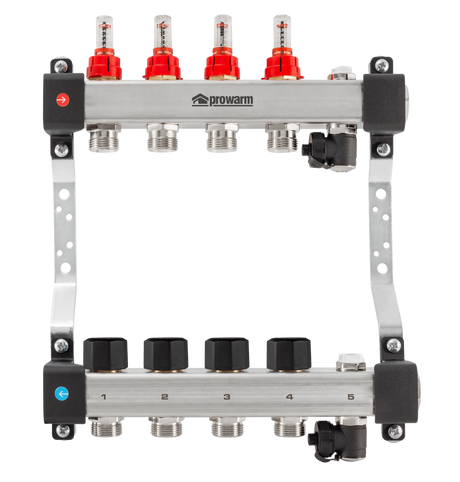

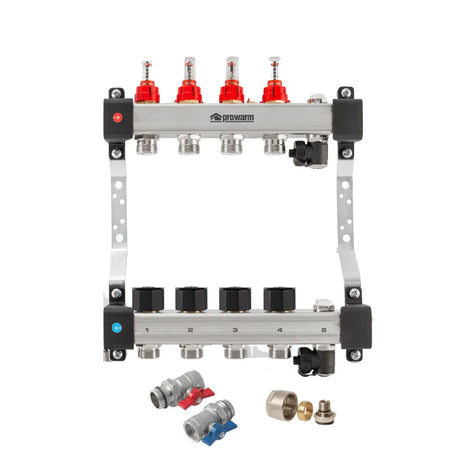

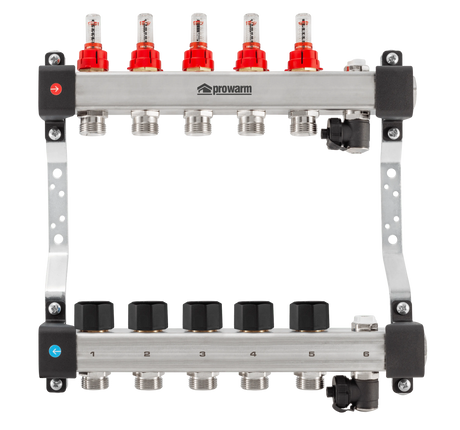

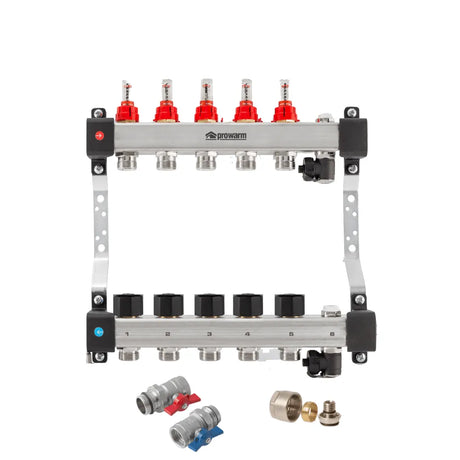

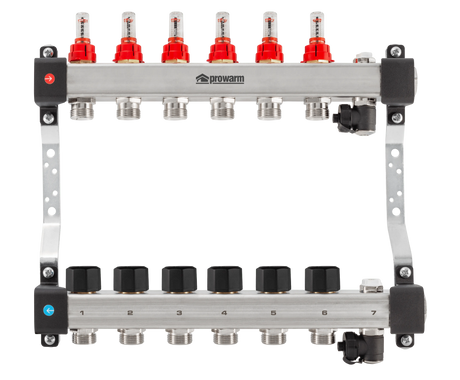

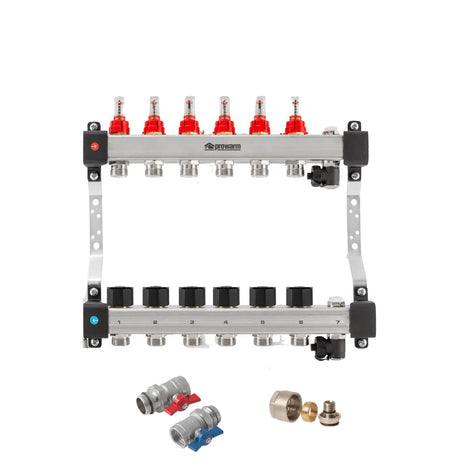

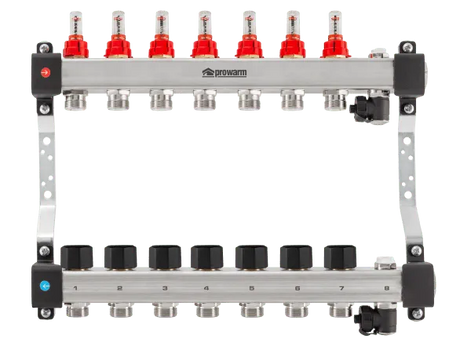

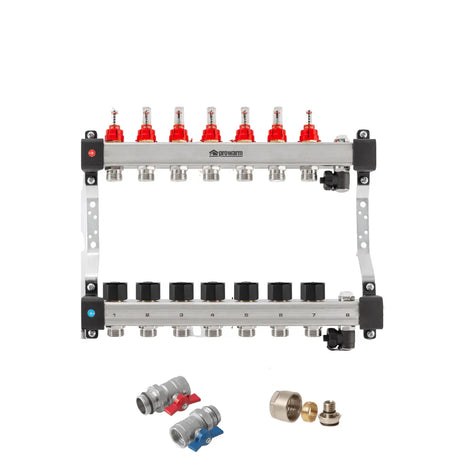

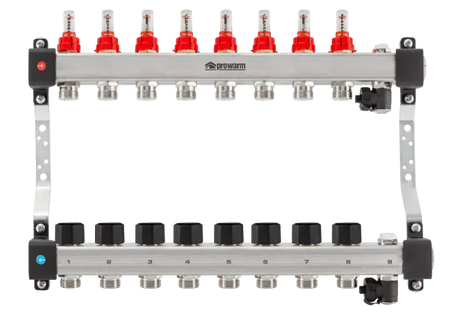

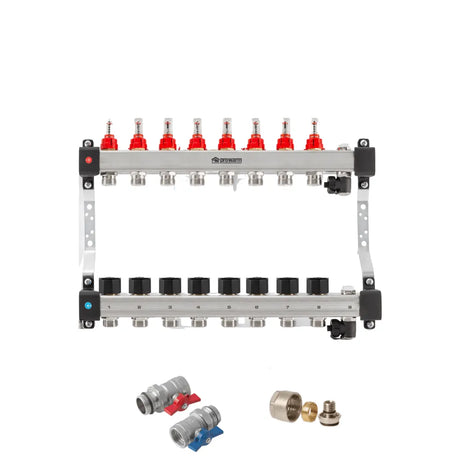

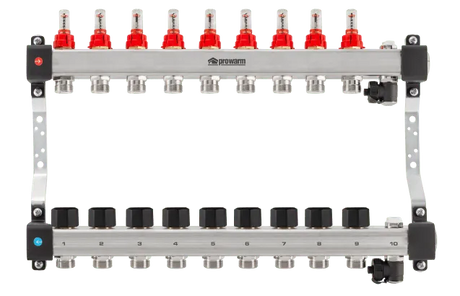

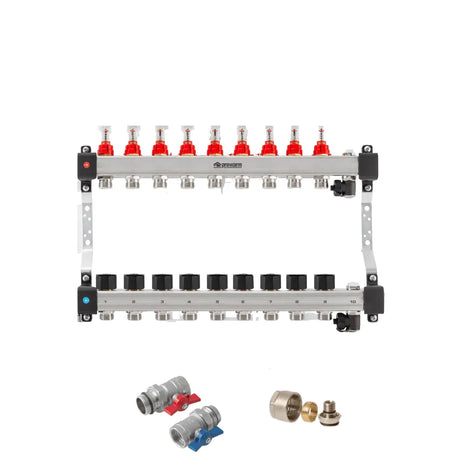

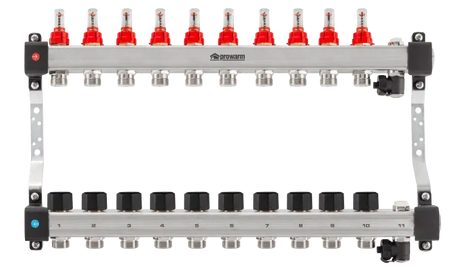

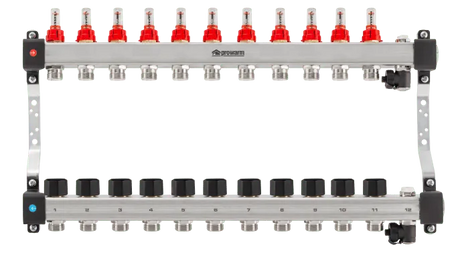

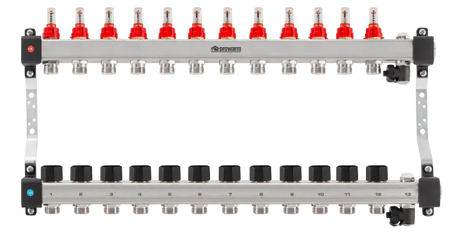

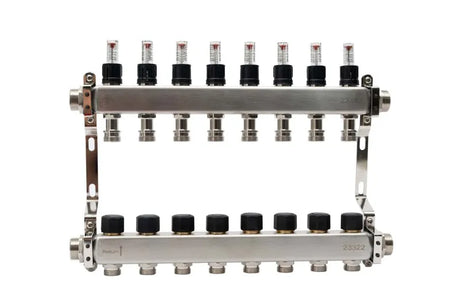

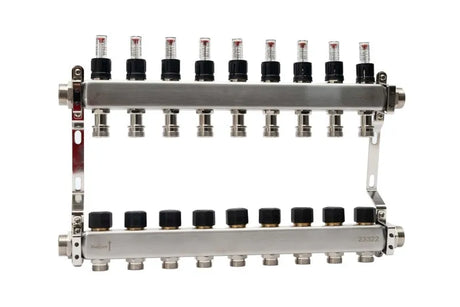

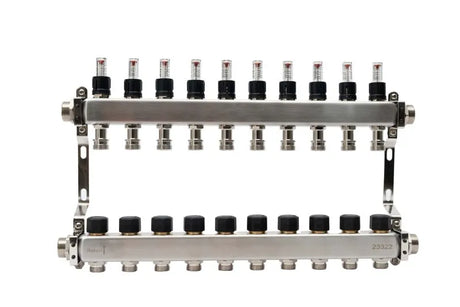

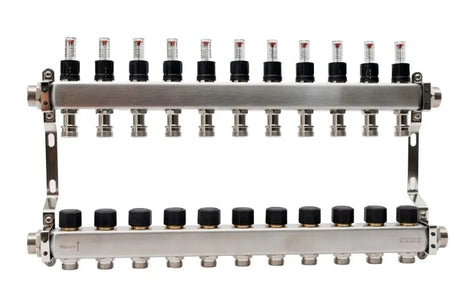

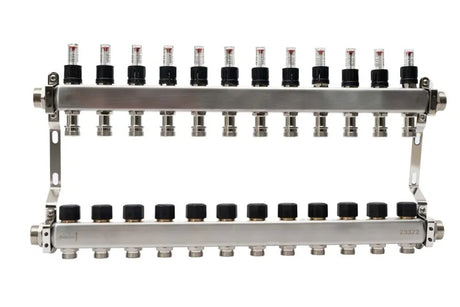

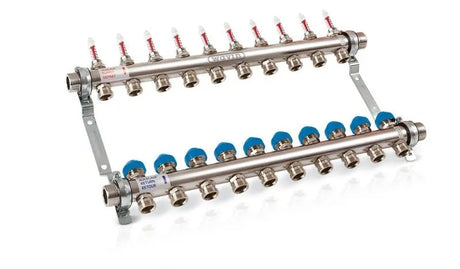

Flow Manifold Rail

This houses all the flow ports and flow meters.

Return Manifold Rail

This holds all the return ports and flow caps.

Flow Meter

This measures the flow rate of water passing through each loop. One is required for each port.

Flow Ball Valve

This unit provides a flow shut-off mechanism.

Return Ball Valve

This also provides a return shut-off mechanism.

Flow Pipe Connection Port

This is for connecting one end of the pipe to the manifold.

Return Pipe Connection Port

This is where the return end of the pipes are connected.

Pressure Gauge

This allows for monitoring the pressure within the manifold.

Air Vent

This is for releasing or bleeding trapped air in the system.

Fill Port

This port is used to fill the system with water.

Drain Port

This port is used to drain the system.

Frequently Asked Questions

Where Should I Put An Underfloor Heating Manifold?

Where Should I Put An Underfloor Heating Manifold?

An underfloor heating manifold is best placed in a central position, which will reduce the length of pipework required. Less pipework will help the system work much more efficiently. A cupboard under the stairs is a popular choice, so too is near a bathroom, kitchen or utility room.

How long will it take to receive my order?

How long will it take to receive my order?

Simply adjust and set the flow meters to increase or decrease the flow rate. The underfloor heating design should indicate the correct flow rates.

How Big Is An Underfloor Heating Manifold?

How Big Is An Underfloor Heating Manifold?

This will depend on the total number of ports. For example, a 2-port manifold will be around 200mm wide, whereas a 12-port manifold will be around 700mm wide. The height of a standard underfloor heating manifold will be between 345mm and 395mm.

Check out our underfloor heating manifolds.